Machine Construction

Machine construction refers to the process of designing, fabricating, assembling, and testing machinery or mechanical systems used in various industries such as manufacturing, construction, agriculture, and more. It involves a combination of engineering principles, material science, and advanced manufacturing techniques to create machines that perform specific tasks, often to improve efficiency, productivity, or safety.

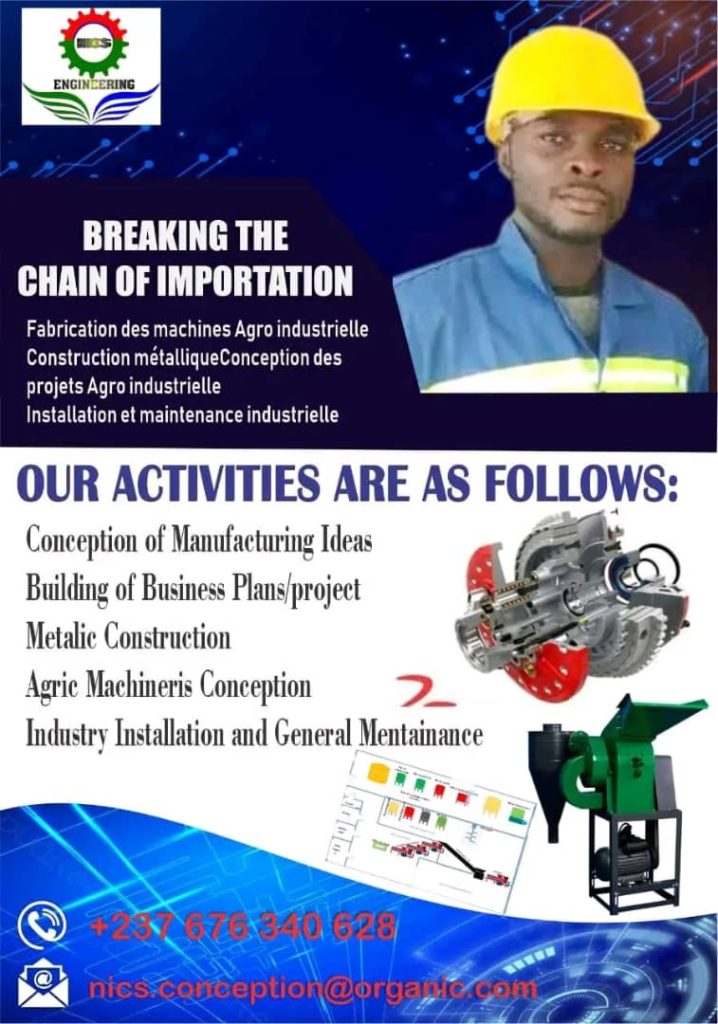

We specialize in designing and constructing agricultural machinery, metallic structures, and industrial installations. Also, we excels in building business plans and projects, as well as offering comprehensive maintenance services for industrial equipment. By fostering local production

NICS Engineering, with our motto “Breaking the Chain of Importation,” focuses on developing and manufacturing solutions for various industries. NICS Engineering aims to reduce reliance on imports, promoting growth and innovation in agricultural and industrial sectors through tailored, high-quality machinery and services.

NICS Engineering’s activities include:

- Conception and manufacturing of machinery.

- Building business plans and projects.

- Metallic construction services.

- Design and production of agricultural machinery.

- Installation of industrial systems.

- General maintenance services for industrial equipment and machinery.

These services aim to enhance industrial self-sufficiency and reduce dependence on imports.

Key Components of Machine Construction and Manufacturing:

Design and Engineering:

- Concept Development: Engineers begin by identifying the purpose and functionality of the machine, considering factors like performance requirements, safety standards, and user needs.

- Computer-Aided Design (CAD): CAD software is used to create detailed models and drawings of the machine components, enabling simulations and analyses to optimize design for functionality and manufacturability.

- Prototyping: Often, prototypes are built to test the design concepts before moving to full-scale production, allowing for adjustments and improvements based on practical feedback.

Material Selection:

- Choosing the right materials is critical to the machine’s performance, durability, and cost. Common materials include metals (like steel and aluminum), polymers, and composites, selected based on their mechanical properties, weight, and resistance to environmental factors.

Manufacturing Processes:

- Fabrication Techniques: Various manufacturing processes are employed to create machine components, including:

- Machining: Processes like turning, milling, and grinding are used to achieve precise dimensions and surface finishes.

- Casting and Forging: Used to shape metals into complex geometries and enhance mechanical properties.

- Welding and Assembly: Components are joined together through welding, bolting, or other methods, depending on design requirements.

- Additive Manufacturing: Technologies like 3D printing are increasingly used to create intricate parts or prototypes rapidly.

- Fabrication Techniques: Various manufacturing processes are employed to create machine components, including:

Assembly:

- The fabricated components are assembled into the final machine. This involves systematic organization to ensure correct placement, alignment, and integration of various systems (like mechanical, electrical, and hydraulic components).

Testing and Quality Control:

- Rigorous testing is conducted to verify the machine’s performance, safety, and reliability. This can include functional testing, stress tests, and quality inspections. Adhering to industry standards and regulations is crucial during this stage.

Commissioning and Deployment:

- After successful testing, the machine is commissioned for use. This includes installation in its operational environment, calibration of systems, and training for operators to ensure safe and effective usage.

Maintenance and Support:

- Ongoing maintenance is essential for the longevity and reliability of machines. This includes routine inspections, repairs, and parts replacements. Manufacturers often provide support services and documentation to assist users in maintaining their equipment.

Applications of Machine Conception and Construction:

Machine construction and conception are integral to various industries, including:

- Manufacturing: Production lines, CNC machinery, robotic automation, and specialized tooling.

- Construction: Heavy machinery like excavators, cranes, and concrete mixers.

- Agriculture: Tractors, harvesters, and irrigation equipment.

- Automotive and Aerospace: Engines, transmission systems, and safety equipment.

- Consumer Goods: Appliances, electronics, and personal care products.

Conclusion:

Machine construction and manufacturing represent a critical intersection of design, engineering, and production. The evolution of this field continues to shape industries by introducing advanced technologies and methodologies that enhance productivity, safety, and innovation, driving the development of new machines and systems that meet the needs of modern society.